-

-

Automotive

High-speed Packaging

Home Appliance

3C/5G

Fitting and Construction Castings

-

We have a powerful spare parts support system worldwide, and you can check our spare parts inventory here.

We have a powerful spare parts support system worldwide, and you can check our spare parts inventory here.

We have a powerful spare parts support system worldwide, and you can check our spare parts inventory here.

-

-1.jpg)

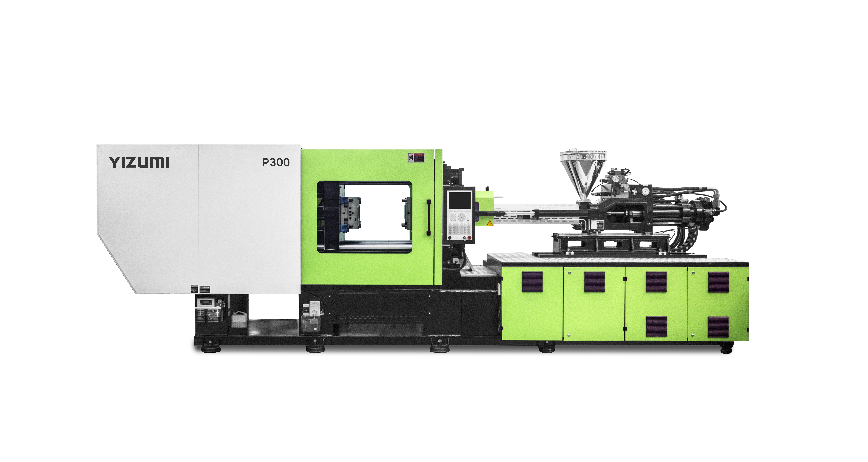

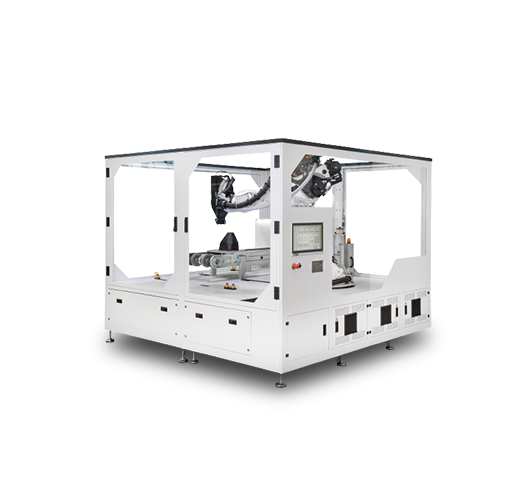

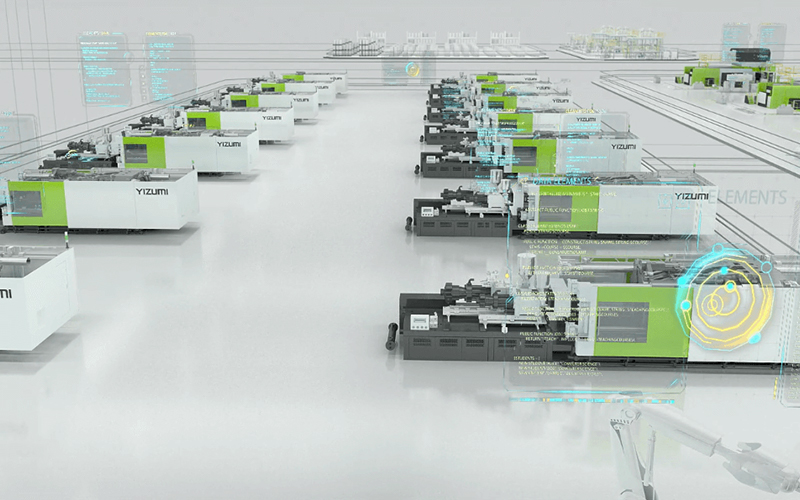

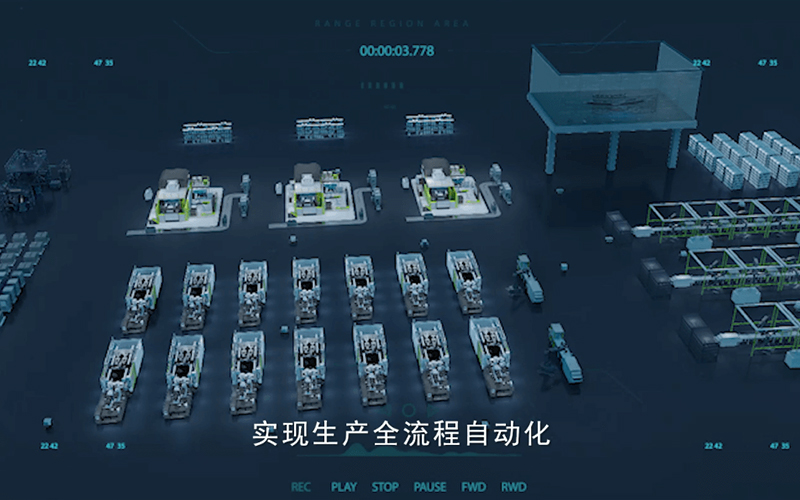

More advanced molding equipment system service provider.

-1.jpg)

More advanced molding equipment system service provider.

-1.jpg)

More advanced molding equipment system service provider.

-1.jpg)

More advanced molding equipment system service provider.

-1.jpg)

More advanced molding equipment system service provider.